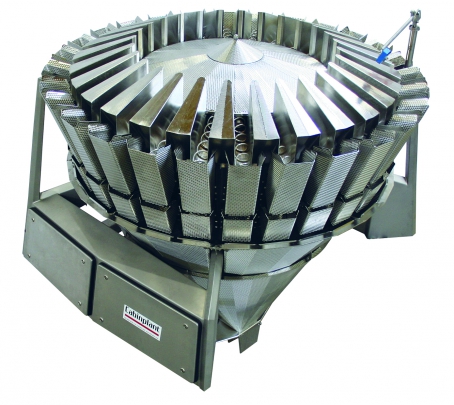

Multihead weigher with screw feeding

The screw feeding system screw feeds the product into assembling pans by means of time and speed control of the worm gear drive. This unique solution is patented.

Charakteristika

Výrobce stroje

Roesbjergvej 9

DK-5683 Haarby

Denmark

tel.:+45 40752276

PGR@cabinplant.com

www.cabinplant.com

Detailní popis

Machine description:

The Cabinplant screw feeding multihead weigher has been granted several patents worldwide for its unique ability to handle difficult products - fragile, wet or sticky. The screw feeding system screw feeds the product into assembling pans by means of time and speed control of the worm gear drive.

The Cabinplant screw feeding principle has introduced the benefits of multihead weighing to processors of wet and sticky products and has made it possible for industries in the meat, poultry, seafood, vegetable, confectionary and ready meal industries to achieve higher weighing accuracy and to reduce give-away costs considerably. In addition, our customers have benefitted from a quick ROI. With a Cabinplant screw feeding multihead weigher you get a well-proven and reliable weighing machine. Our screw feeding multihead weighers are available in a wide range of models, and we can offer you a machine that will meet your specific demands and ensure optimal handling of your product.

The screw feeding multihead weigher is also available with sensor gates.

The sensor gates ensure optimal feeding of each assembling pan – i.e. feeding of only one piece of product into each pan, thus obtaining the highest possible number of combinations and achieving the highest degree of accuracy.

Capacity: 20 – 225 portions per minute. The capacity depends on several parameters - e.g. product characteristics, production temperature, etc.

Main features:

- Continuous weighing

- Few-piece portions

- Retrofit existing lines

- No give-away when handling small negative tolerances

- Specially adapted product contact materials for handling of sticky products

- Minimum noise level

- Minimum maintenancee

- Easy cleaning

- Wireless operator panel

- Fast return on investment

Type of weighing:

- Single or multiple weighing

- Flow weighing

- Floating set-point weighing

- Single dynamic weighing (SDW)

- Dual dynamic weighing

Technická data

| Capacity Pan size weighing channels |

Portion size each |

Portions |

Mix weighing |

Length [mm] |

Height [mm] |

Width [mm] |

Weight [kg] |

| 10-12 | 1 | 20-100 | 1-2 | 1.300 | 1.080 | 1.750 | 500 |

| 10-14 | 1 | 25-125 | 1-2 | 1.460 | 1.210 | 1.830 | 550 |

| 10-18 | 1 | 30-150 | 1-2-3 | 1.600 | 1.290 | 1.870 | 650 |

| 10-24 | 1 | 40-200 | 1-2-3-4 | 1.690 | 1.560 | 2.100 | 950 |

| 10-28 | 1 | 45-225 | 1-2-3-4 | 2.000 | 1.820 | 2.330 | 1.150 |

| 30-10 | 3 | 20-100 | 1-2 | 1.420 | 1.170 | 1.860 | 500 |

| 30-14 | 3 | 25-125 | 1-2 | 1.470 | 1.260 | 1.900 | 600 |

| 30-20 | 3 | 30-150 | 1-2-3 | 1.700 | 1.610 | 2.200 | 900 |

| 30-24 | 3 | 40-200 | 1-2-3-4 | 1.940 | 1.820 | 2.300 | 1.000 |

| 30-28 | 3 | 45-225 | 1-2-3-4 | 2.180 | 2.080 | 2.340 | 1.100 |

| 40-10 | 4 | 20-100 | 1-2 | 1.560 | 1.310 | 2.100 | 650 |

| 40-14 | 4 | 25-125 | 1-2 | 1.760 | 1.560 | 2.200 | 700 |

| 40-20 | 4 | 30-150 | 1-2-3 | 1.940 | 1.870 | 2.230 | 1.000 |

| 40-24 | 4 | 40-200 | 1-2-3-4 | 2.180 | 2.130 | 2.680 | 1.100 |

| 50-14 | 4 | 25-125 | 1-2 | 1.990 | 1.960 | 2.650 | 800 |

| 50-20 | 4 | 30-150 | 1-2-3-4 | 2.460 | 2.460 | 2.800 | 1.300 |

Aplikace

For difficult, sticky and wet products such as: fresh meat, poultry, fish & seafood, pasta, cabbage etc.